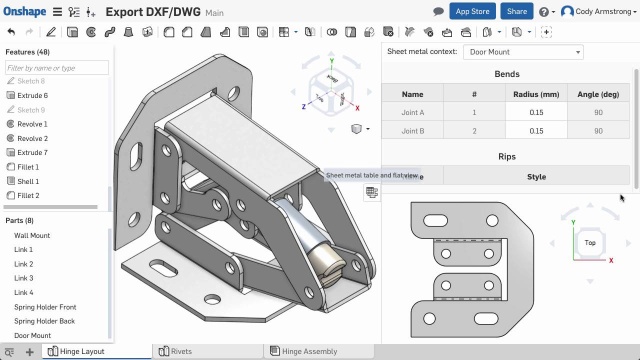

Below is the basic example of the flat and flanged walls.

Creo sheet metal flange vs flat.

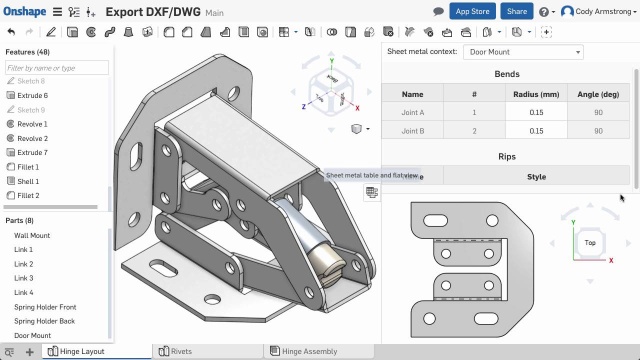

The flat pattern feature is persistent about being the last feature in a model tree.

Flat wall gives you control over the profile of the wall.

Changing a bend with the constant flange lengthoption selected.

The flat pattern displays the corner relief as set in the relief area of the sheetmetal preferences dialog box.

Information regarding the difference of flange and flat wall features for sheet metal.

In the image below i would like to bend along the construction like that is 2 009 away from the righ.

20 oct 2016 applies to pro engineer and creo elements pro wildfire to wildfire 5 0.

Constant flat lengthensures that the length of the unfolded wall is not changed.

There is a way around this using simplified reps.

Changing a bend with the constant flat lengthoption selected.

As one who daily works with sheet metal design and fabrication use outside flange lengths for several reasons.

It purely depends upon the shape of the part that decides which one to use.

Constant flange lengthkeeps the distance between the apex and the end of the wall fixed.

I am able to make the flat flange from a dxf but do not want to bend along and edge but rather bend part way down the face of the file.

No worries of forgetting a material thickness along the way 3.

When you use the corner relief flange or conversion tools to create feature specific relief then the flat pattern displays the relief as you set it using the tools.

Flange wall gives you control over the cross section of the wall.

Here is the basic explanation for the two sheet metal options.

When you figure flat pattern length you simple add up all the outside flanges and subtract the bend deductions.