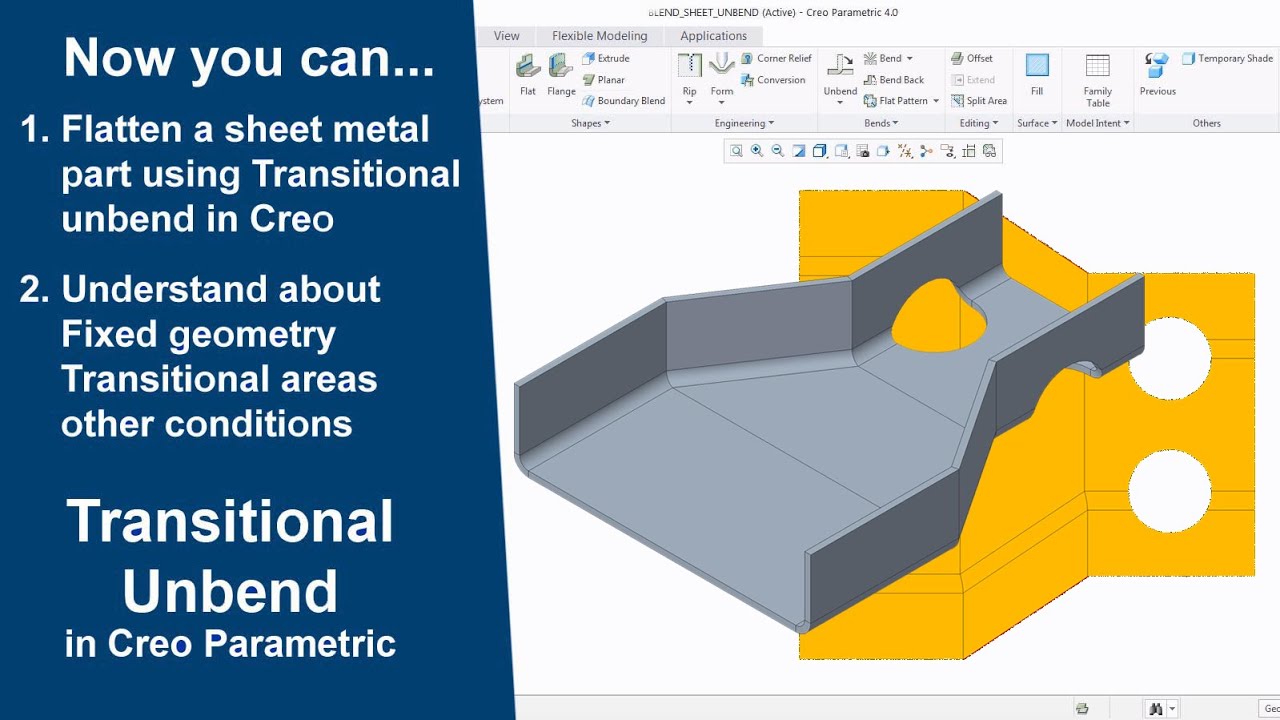

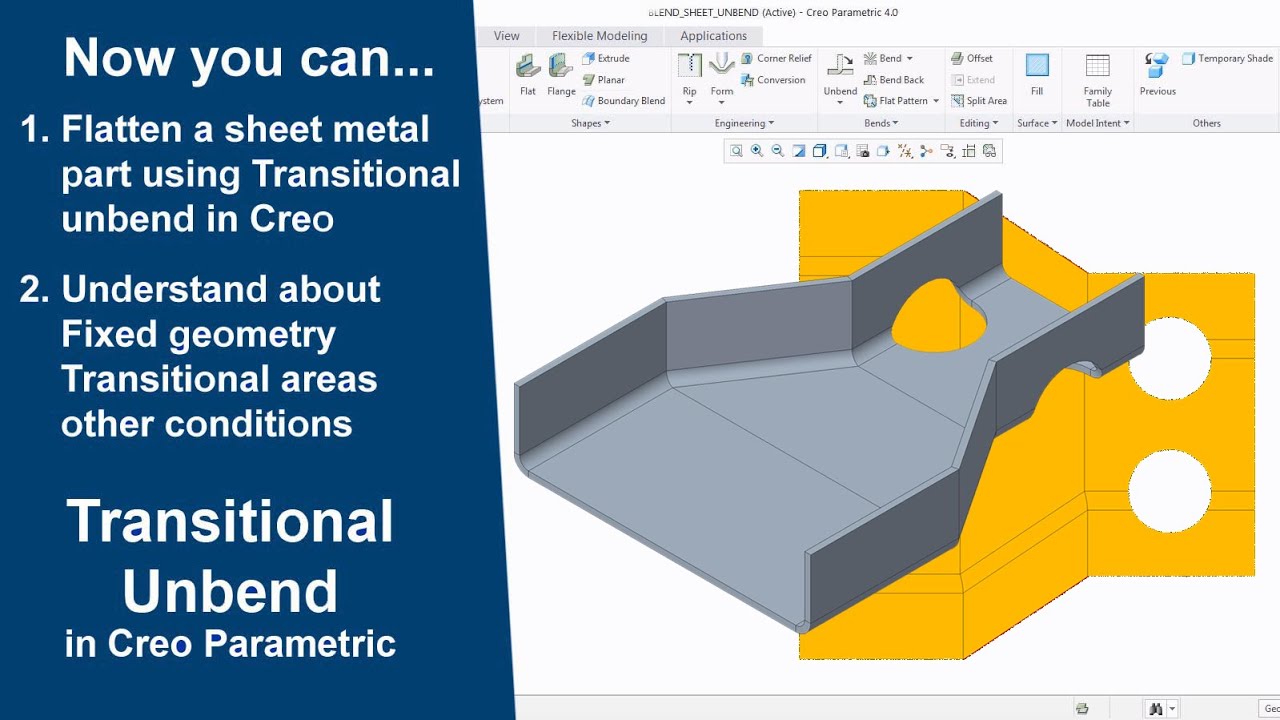

Difference between sheetmetal flange flat features in pro engineer and creo parametric modified.

Creo sheet metal flat vs flanged.

From creo parametric 5 0 release the depth option tangent to bend in not available.

As one who daily works with sheet metal design and fabrication use outside flange lengths for several reasons.

Sheetmetal fold vs.

If i understand the sticking point of the question how can it be done using the sheet metal module of proe vs extruding.

Sheet metal corner relief and self intersecting flange ratso mechanical 27 jul 06 04 14 ok i have done a sample based on your info and the downloaded ipt.

Dave does your sheet metal part have a stepped flange as shown in the wikipedia picture on the right.

When you figure flat pattern length you simple add up all the outside flanges and subtract the bend deductions.

When the tangent to bend depth option is used in a relation the relation is maintained but the result produced will be the.

Constant flange length keeps the distance between the apex and the end of the wall fixed.

When i create the main bend with a radius of about 0 09 i tend to lose varying amounts of material to create it.

Flange i am currently attempting to set up user friendly templates for the various types of v clips i work with and i have a small dilema.

Or is it just a flat piece you are adding the joggle.

Information regarding the difference of flange and flat wall features for sheet metal.

Flat wall gives you control over the profile of the wall.

Flange wall gives you control over the cross section of the wall.

Constant flat length ensures that the length of the unfolded wall is not changed.

No worries of forgetting a material thickness along the way 3.

Here is the basic explanation for the two sheet metal options.

20 oct 2016 applies to pro engineer and creo elements pro wildfire to wildfire 5 0.

It purely depends upon the shape of the part that decides which one to use.