Increases the time required between watering intervals.

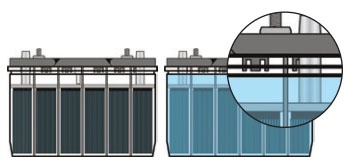

Crown forklift battery watering system.

Make sure to look for information on the battery labeling that indicate whether the battery can be opened and serviced.

Forklift battery repair liquid solution 36 volt 36 bottles 5 0 out of 5 stars 1.

350a battery connector 2 0 awg gray 350a 600v plug quick connector disconnector housing 2 pole.

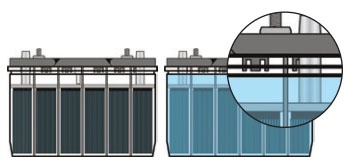

Once installed the entire watering process takes less than one minute per battery.

By using a watering system your batteries can be filled faster and more accurately.

With h2go by crown battery the intervals between watering are 9 12 weeks depending on application and usage.

Forklift battery watering system battery filler system.

Depending upon the battery type you are using the warning labels on your battery should direct you to do not open the battery or keep vent caps tight following watering service.

A 6 pack of caps plus a battery filling squeeze bulb.

Bfs new battery filling watering system for hi lo forklifts 18 cell 33mm.

Standard industrial batteries require normal watering maintenance every 1 3 weeks or about 16 to 50 times per year.

Once connected water flows into each cell until it reaches the correct level.

The leader in battery watering technologies kit selector quickly find the exact part number and prestrung layout for your battery media catalogs need to download literature or operating instructions.

A quick coupling allows the watering system to be connected to a water supply.

Gb industrial battery forklift batteries and chargers.

Crown s v force series forklift battery watering systems save battery maintenance time and money by maximizing battery life without the need for a battery watering cart or battery watering gun.